Routes to digitalisation in agriculture

Over the past few decades, agriculture has evolved from being a sector that was once heavily reliant on manual labour to one that is now highly mechanised. Mechanisation leads to a rise in complexity, meaning more and more decisions have to be made simultaneously. Working with precision requires sophisticated sensors and decision-making tools, and systems that are capable of inter-communication. To maintain visibility and control, processes are largely automated and work steps are documented to a high degree of accuracy. Fields are extremely variable in terms of their regrowth and soil structure, which means a great deal of decisions need to be made in order to farm them efficiently. This is exactly where the benefits of precision farming or precision agriculture come in. The proponents of this development are politicians, scientists, society as a whole and the agricultural industry itself. Contextual scientific knowledge of crop growing indicates areas where resources can be saved and greenhouse gases reduced, while political frameworks and societal demands determine the playing field and set the course. The growing societal demands and legal requirements in farming have the potential to be solved through rapidly evolving technology. The rising price pressure as a result of international competition also requires an industry-wide boost in production efficiency for agricultural goods.

Driving forces for change

The push for digitalisation has penetrated all areas of agriculture, so the industry is not alone in facing its challenges. Agriculture also benefits from the progress that is being made, for example in information technology. Positioning systems for determining exact locations are a core example of progress in this area. Freely available satellite data has enabled the technology to come on in leaps and bounds. The location data of machines can be accurately measured to a few centimetres through a combination of various processes. Technical solutions for electronic machine controls, such as part width section control in plant protection, as well as drive controls and metering equipment in fertiliser spreaders and seed drills, can all benefit from this. Special sensors are also required to record the status of crops, for example. The digitalisation path in arable farming leads to a process chain of data-driven crop production.

The market for precision agriculture is now widely developed and there are various providers of complete farm management information systems, which are not only useful on the field, but also in the barn and across the entire farm. So much so that it begs the question – where do I start?! And what are the issues and challenges within this domain?

The first challenge usually begins during implementation. Converting to a new system involves investing a great deal of time in the beginning. Then there are the financial risks. This is where a cost-benefit analysis must be carried out. The decision on which applications to use and whether they will be practicable in the long term is another big challenge. Simply gathering data is not enough on its own; the data also needs to be visualised and evaluated. Depending on the information produced, activities can then be planned and implemented as a next step. This requires suitable communication channels, interfaces, machines and implements. After all, an application map isn’t much use to an ox. In essence, farms need to be aware that there are multiple factors and various systems at play when it comes to implementation.

The second biggest challenge comes in adapting the system to local conditions. Network coverage is often problematic. In terms of data recording, the functions should ideally be set up in a way that enables data to be saved to each mobile device then synchronised with the associated cloud storage system once they are back online. Local conditions also incorporate the specific farm structure. The connectivity of systems and machines is often a hurdle in this case. Agricultural contractors, in particular, have mixed fleets and some of their machines are more digital than others. Coordinating the individual components is crucial and presents a huge challenge. If one machine is already highly digitalised, the surrounding machines often have to catch up to a certain degree in order to be able to communicate smoothly. Standardisations, manufacturer-independent applications and options for connecting analogue farm machinery offer one solution to the problem. Those operating the machines must also be taken into consideration. They need intuitive programmes that offer clear, user-friendly functions.

Current areas of application and processes in agriculture

There is no exact definition of precision agriculture or precision farming that is recognised across the board. The terms are used to describe various areas of agriculture. The concept represents more than just technology for dealing with variable local conditions – it is also about designing the entire process chain and managing information. It involves a combination of different components. Precision farming incorporates automatic data recording as a basis, section-specific equipment for all crop cultivation activities, fleet management (location, route planning, machine data monitoring) and field robotics (automated implement control for manned and unmanned vehicles).

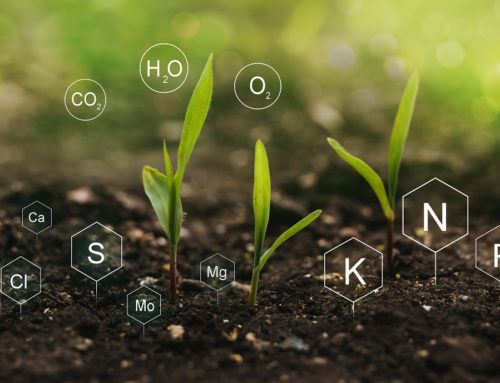

In principle, a distinction is made between online and offline processes. Field potential and application maps are generated in advance then transmitted – often manually – in separate work steps to the tractor’s terminal. This is what is referred to as the offline process. The machines are then guided by the stored GPS data to perform the crop cultivation tasks. Therefore, having a stable GPS signal is essential for autonomous driving and steered implements. As part of the online process, the data is captured at the exact moment the task is carried out. During plant protection activities, for example, information about the crop is recorded by sensor equipment mounted on the front of the tractor. Based on the information gathered, the controls for the attached sprayer are influenced via specific target values. The information is exchanged in a split second via electronic communications between the relevant components. Similar processes can be used when spreading fertiliser. Good sensor equipment that draws on different processes is therefore required. This enables information on the nitrogen supply, weed infestation, biomass level and disease infestation to be detected. Optical sensors utilise the property of plants to absorb and reflect less red light during photosynthesis. This enables the active biomass to be determined. In near infrared spectroscopy (NIR), the opposite effect is used. Plant structures reflect near infrared light, which is not present on the spectrum visible to human eyes. It produces a characteristic reflection spectrum, which indicates the condition of the crops on the field. To assess the presence of disease, thermal sensors can be used to measure the surface temperature of leaves, which enables healthy leaves to be distinguished from diseased leaves when a fungal infestation is present.

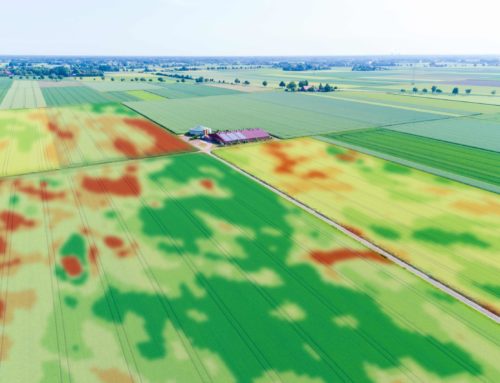

In the past, farmers have often been accused of not producing enough documentation. A lack of time, valid measurements and standardised formats has tended to be the reason. Ultimately, the data also needs to be evaluated and interpreted. Things are much simpler now thanks to the modern technology. In order to transform the measured values into information, the data must first be recorded and stored. In precision agriculture, this takes place automatically as each task is completed. Using the machine’s GPS signal, the data can also be allocated to a specific position on the field and presented on various maps. The main areas of application are yield maps, which are based on information gathered from harvesters, and vegetation maps, which incorporate satellite data. Another option is to incorporate soil sampling results so they can be illustrated on the field map. These map resources enable crop cultivation activities to be planned and implemented in a targeted manner.

In the future, the momentum for digitalisation is bound to be even stronger. The development of field and barn robots on farms is far from over. Robots are often seen in barns nowadays, but they’re less common in the field. Machines are capable of sowing a field or controlling weeds with the help of sensors and achieve a similar acreage performance to their larger relatives. There is still plenty of room for development in the robotics domain. In the software domain, providers who can adapt dynamically to the needs of both their users and the industry are the ones that will stay the course.